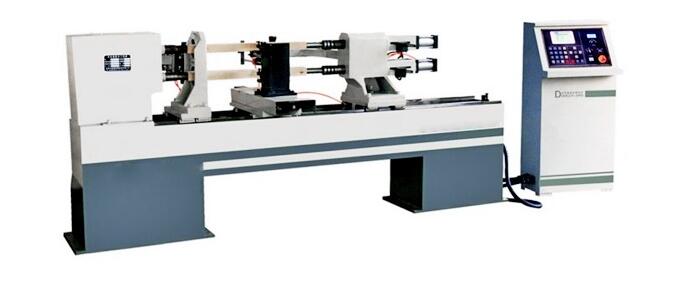

With the improvement of people's consumption level, the demand for wooden staircases and dining tables also increased rapidly. In this context, the manufacture of wooden staircase handrails and table legs has become a bottleneck in the furniture industry, automatic CNC woodworking lathes came into being.

First, the characteristics of CNC woodworking lathe:

1. The operating system is simple and friendly Chinese interface, easy to operate.

2. High precision, with a stable processing quality. Wood surface processing quality than ordinary carpentry lathe, followed by grinding work greatly reduced, can improve work efficiency.

3. there are four automatic tool changer electric knife.

4. Processing parts change, generally only need to change the NC program, can save production preparation time.

5. The machine itself is high precision, strong rigidity.

CNC woodworking lathe is a two-axis linkage, semi-closed-loop control. With high rigidity of the structural design and shock absorption to ensure high precision machining. The servo drives and motors that control the axes X and Z have high dynamic response characteristics and precise positioning accuracy, which makes the tool holder move fast, stable and high in positioning accuracy.

For the machine spindle, must be high-speed, high rigidity of the spindle, a fast start and stop characteristics, with high efficiency and low noise design, which can make the parts of the processing efficiency, high precision, high speed means high production effectiveness.

Second, the system design:

CNC lathe system architecture

(1) CNC control system

(2) spindle system: spindle motor

(3) X-axis drive system: 750W a set

(4) Y-axis drive system: 1KW a set, for the feed shaft X, Z servo performance requirements are mainly servo system has a higher dynamic response and high positioning accuracy. Power cycle servo based on DSP + FPGA + IPM hardware platform, has a high-speed frequency response, speed response bandwidth of 450HZ, living in the forefront of domestic servo; with resonance suppression function, can be accurately tuned to eliminate vibration; control accuracy can reach a pulse , The maximum input frequency can reach 500Kpps, which are very good to ensure that the required drive shaft drive requirements.

Third, the summary:

As an important function of CNC machine tools, the characteristics of servo system has always been an important indicator of system performance. Li Chuan servo very good to meet the requirements of the CNC industry, for the domestic CNC industry has made its own contribution.