Driver Function | operation Insulation |

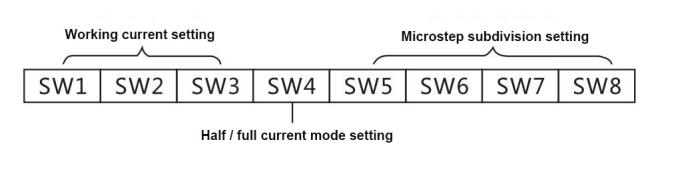

Microsteps Sudivision setting | SW5-SW8 four DIP switches to set the drive micro-step subdivision, a total of 15 steps of mic ro-step breakdown. When the user sets the subdivision, the drive should be stopped first. For details on the numberof microsteps,Please according to the drive panel. |

Working current setting | SW1-SW3 three DIP switches to set the drive output current, the output current of a totalof 8 floor.Details on setting the output current,refer to the description of the driver panel. |

Automatic half current Function | SW4 can be used to set the automatic semi-flow function of the drive. OFF mean the quiescent current is set to half of the dynamic current, and ON means the quiescent current is the same as the dynamic current SW4 should be set to OFF for general use, resulting in reduced heat generation in the motor an the drive, resulting in improved reliability. Approximately 0.4 seconds after the pulse train is stopped, the current automatically reduced by 50% (60% of the actual value) and the calorific value is oretically reduced by 36%. |

Signal interface | PUL + and PUL- are the positive and negative terminals of the control pulsesignal;DIR + and DIR- are the positive and negative terminalsof the directional signal;ENA + and ENA- are the positive & negative terminals of the enable signal. |

Motor interface | U,V,W corresponding to the motor winding wire U,V,W any two pairs of the three winding wire ,the motor can change the direction. |

| Indicator light | The driver has two red and green lights. The green light is the power indicator, the green light is on when the driver is powered on. The red light is the fault indicator. When the overvoltage or overcurrent fault occurs, the fault light is on.Fault clear, the red light off. When the drive fails, the fault can only be cleared by re-powering up and re-enabling it. |

Power supply Port | DC power supply, the input voltage range: 20V-50VDC,Power more than 200W,suggest the working voltage 36V . |

Installation Notes | Driver dimension :117x78x34mm ,installation the hole spacing of 111mm can be horizontal or vertical mounting (suggest the vertical installation) when installed ,mke it close to the metal cabinet to facllitate heat . |

LC3056MA driver with eight DIP switch set subdivision accuracy, dynamic current and half-flow / full-flow, described in detail as follows:

Working current setting :

| Mean current | SW1 | SW2 | SW3 |

1.35A | off | off | off |

1.86A | on | off | off |

2.6A | off | on | off |

3.2A | on | on | off |

3.8A | off | off | on |

4.45A | on | off | on |

5.2A | off | on | on |

5.8A | on | on | on |

Microstep settings :

| Step/turn | SW5 | SW6 | SW7 | SW8 |

200 | off | off | off | off |

400 | on | off | off | off |

500 | off | on | off | off |

800 | on | on | off | off |

1000 | off | off | on | off |

1250 | on | off | on | off |

1600 | off | on | on | off |

2000 | on | on | on | off |

2500 | off | off | off | on |

3200 | on | off | off | on |

4000 | off | on | off | on |

5000 | on | on | off | on |

6400 | off | off | on | on |

8000 | on | off | on | on |

10000 | off | on | on | on |

12800 | on | on | on | on |